Electronic Manufacturing Services (EMS) and production of electronic modules

Electroinvent has production department for Electronic Manufacturing Services (EMS) – SMD and TH assembling. In this way Electroinvent closed the whole production process in the company.

All activities during SMD and TH assembling are executed under standard IPC-A-610

The EMS department is equipped with the following machines:

– Two independent SMD assembling lines, mounting of components from sizes 0402 to QFP, QFN, ICs and BGA :

1st line includes: Loader,Screen printing equipment type SP700 AVI, Pick and place machine type SAMSUNG 421, reflow oven HELLER 1707MKIII, Unloader and Conveyors

2nd line includes: Screen printing equipment type S40, Pick and place machine type PLM200D, reflow oven TWS 1380 and Conveyors

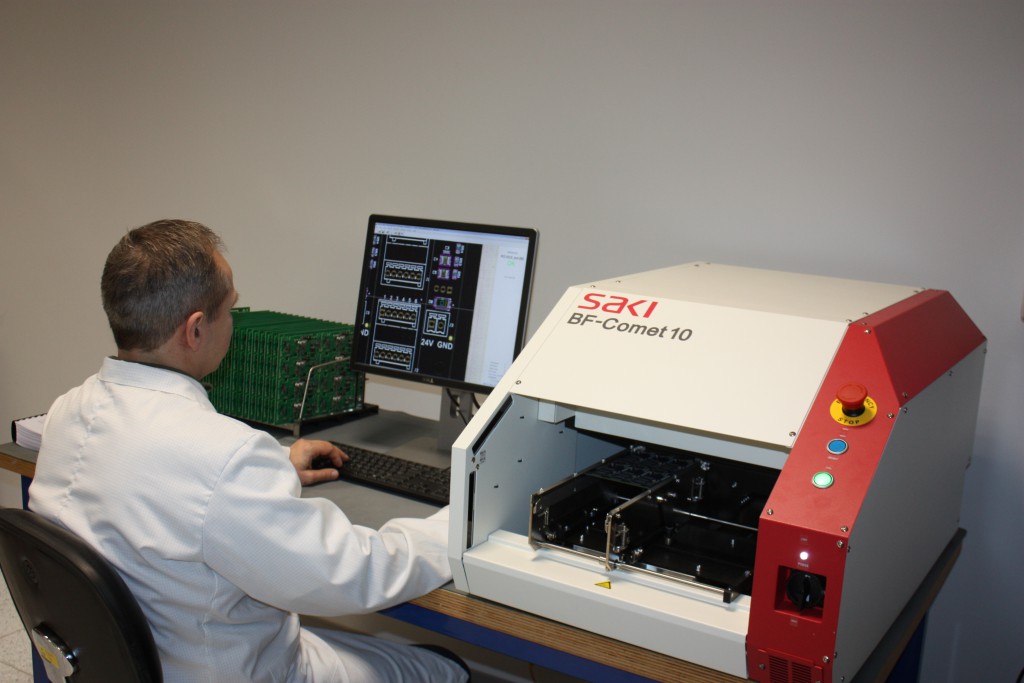

– SAKI BF Comet 10 – Automatic Optical Inspection (AOI) machine

– HEEB INOTEC – Wave Soldering Machine HWL 330

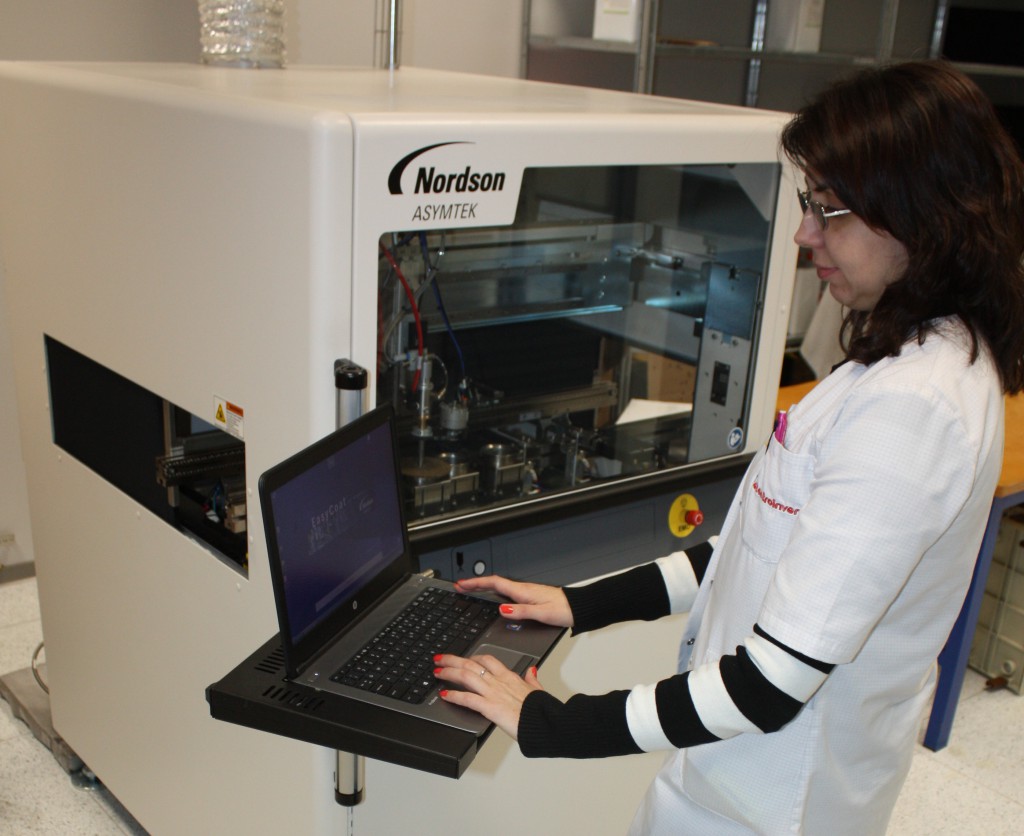

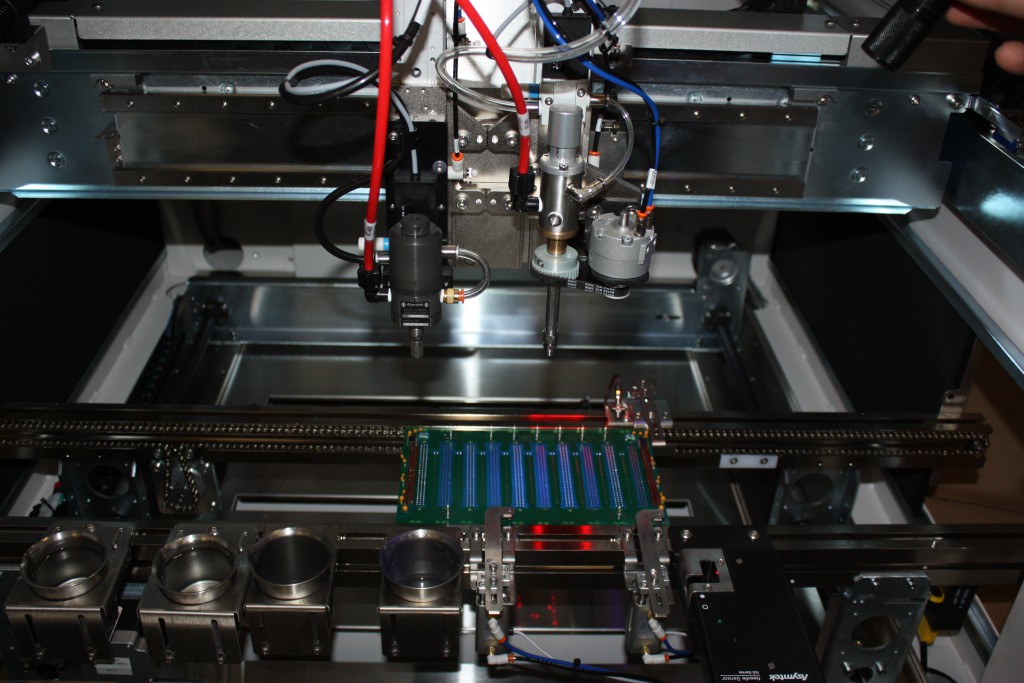

– ASYMTEK Selective Conformal Coating

– ELME Equipment for preparation for Assembling of TH components

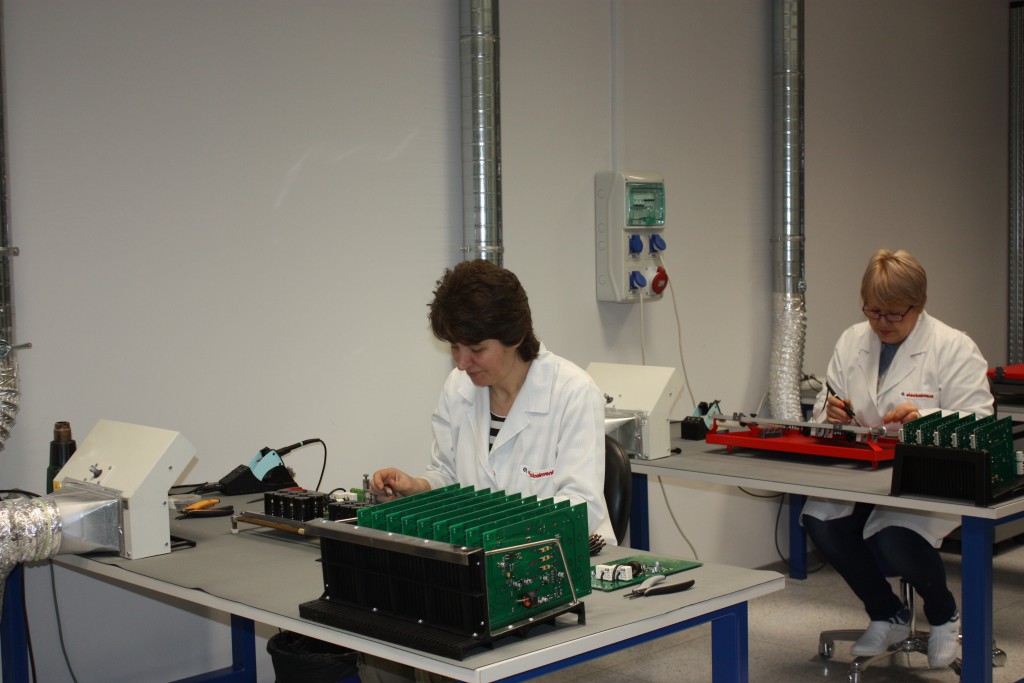

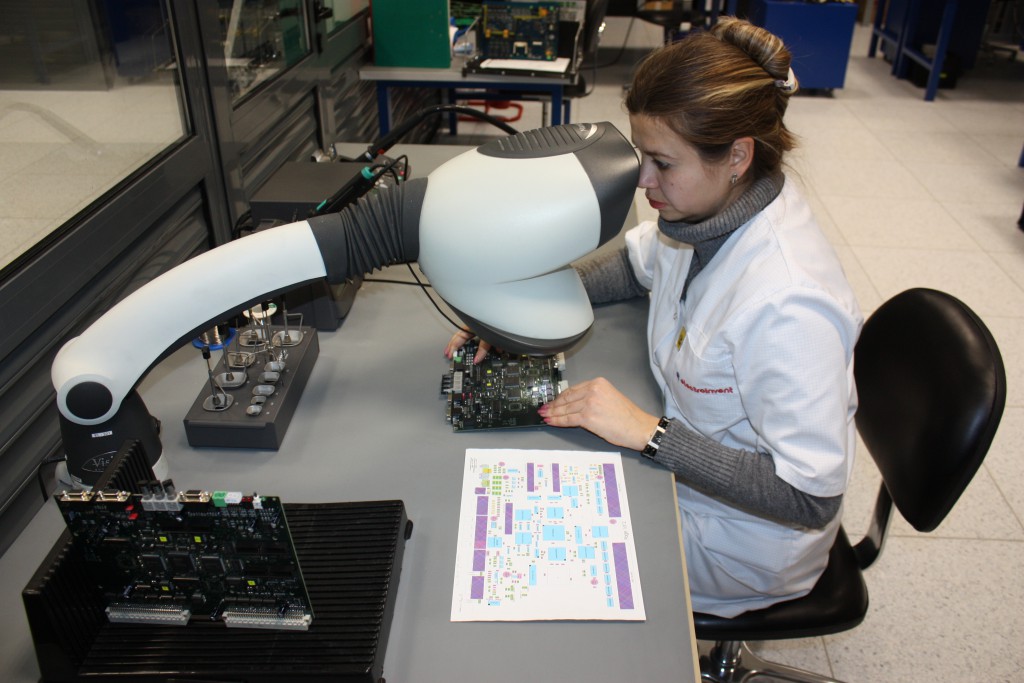

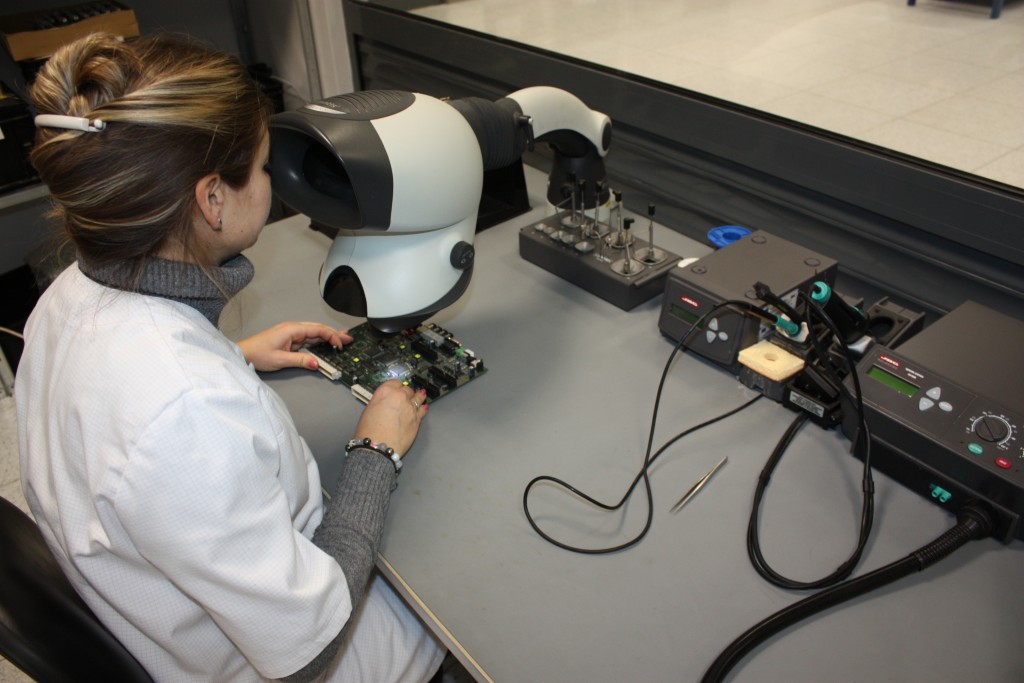

– Working places with JBC equipment for upgrade, rework and repair

– Vision Engineering equipment for visual inspection Mantis